In modern maintenance, installation, and facility operations, vertical mast lifts have become a go-to solution for safe and efficient access to elevated work areas. Compact, lightweight, and designed for maneuverability in tight indoor environments, these machines provide a practical alternative to traditional ladders or bulky aerial work platforms.

This article, Vertical Mast Lifts: Types, Applications, and Benefits, offers a comprehensive overview of the various types of mast lifts available, where and how they're typically used, and the key advantages they bring to different industries. Whether you’re a facility manager, construction professional, or equipment rental provider, understanding the capabilities of vertical mast lifts can help you make smarter, safer choices on the job.

What Is a Vertical Mast Lift?

A vertical mast lift is a type of aerial work platform (AWP) designed for vertical access in confined spaces. Known for its compact footprint, lightweight design, and straight up-and-down lift path, it is ideal for tasks that require reaching overhead areas without horizontal outreach. These lifts are commonly used indoors in environments such as warehouses, retail stores, office buildings, hospitals, and factories where maneuverability and minimal floor load are crucial.

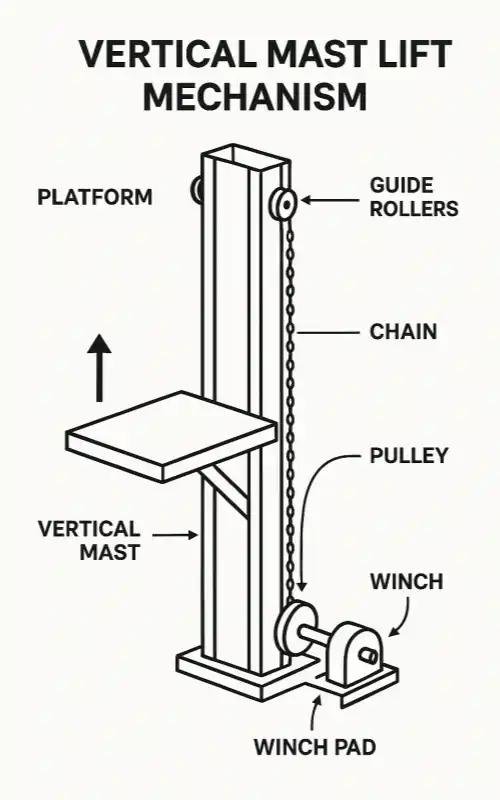

Basic Structure of a Vertical Mast Lift

The core components of a vertical mast lift typically include:

Mast Columns: One or more telescopic aluminum or steel masts that extend vertically.

Work Platform: A small, enclosed standing area for one or two operators.

Base Frame: The foundation that houses the battery or power unit and supports stability.

Lift Mechanism: Operated by hydraulic, electric, or pneumatic power depending on the model.

Control Console: Located on the platform and/or base for maneuvering and elevation control.

Vertical mast lifts are valued for their low overall weight, making them suitable for delicate flooring, such as tiles or mezzanine levels, and for tight access areas where larger equipment cannot reach.

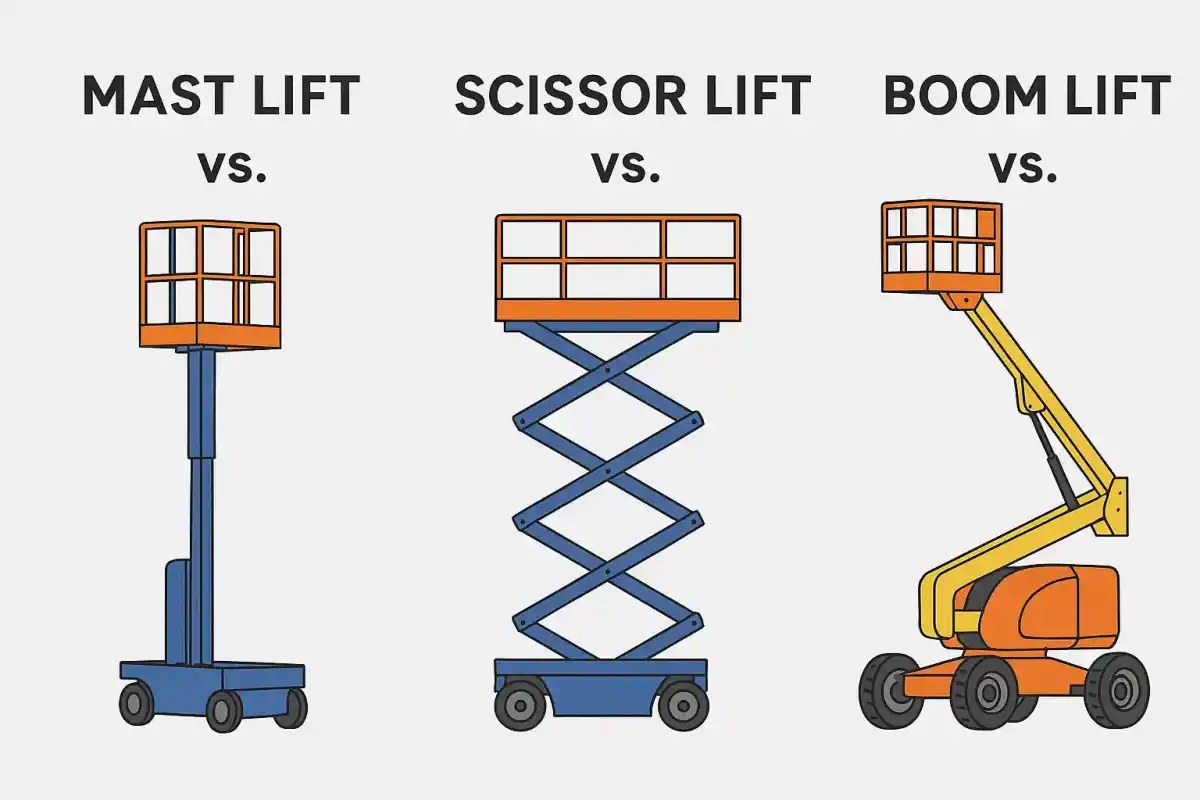

Vertical Mast Lifts vs. Scissor Lifts vs. Boom Lifts

While all three are used for working at heights, vertical mast lifts differ significantly in form and function from scissor lifts and boom lifts:

| Feature | Vertical Mast Lift | Scissor Lift | Boom Lift |

|---|---|---|---|

| Lift Direction | Vertical only | Vertical only | Vertical + Horizontal (articulating) |

| Footprint | Very compact | Larger footprint | Large, requires more clearance |

| Reach | 5–14 meters (typical) | 6–18 meters | Up to 40+ meters with outreach |

| Mobility | Highly maneuverable | Moderate | High, with rotation/boom swing |

| Use Case | Indoor, maintenance | Indoor/outdoor, install | Outdoor, construction & utilities |

| Platform Size | Small (1–2 people) | Medium | Variable (often larger platforms) |

Key Advantage of Vertical Mast Lifts:

They can access narrow aisles, doorways, elevators, and tight corners—making them irreplaceable in certain indoor environments.

Typical Height and Load Capacities

Vertical mast lifts come in a range of sizes and configurations. Below is a summary of typical specifications by category:

| Type | Max Platform Height | Working Height (Approx.) | Load Capacity | Typical Weight |

|---|---|---|---|---|

| Single Mast | 4–6 m | 6–8 m | 130–160 kg | ~400–500 kg |

| Dual Mast | 8–10 m | 10–12 m | 180–200 kg | ~800–1,000 kg |

| Multi-Mast | 12–14 m | 14–16 m | 200–250 kg | 1,000+ kg |

| Self-Propelled | 6–12 m | 8–14 m | 200–230 kg | 1,100–1,400 kg |

Note: "Working Height" is typically calculated as platform height + 2 meters, accounting for the operator’s reach.

Modern models also include features like non-marking tires, zero turning radius, fold-down guardrails, and AC/DC power options, making them even more adaptable to indoor operations.

Vertical mast lifts fill a specific niche in the aerial lift family: small-scale, efficient, vertical-only elevation. Their unique value lies in their ability to perform quick, clean, and safe lifts in environments where traditional lifts simply cannot go.

Types of Vertical Mast Lifts

Vertical Mast Lifts are mobile elevating work platforms (MEWPs) designed to provide workers with access to elevated areas, often in indoor environments or tight spaces. These lifts are commonly used in maintenance, construction, and event setups. Vertical Mast Lifts come in different types depending on their features and applications. Below are the four main types: Single Mast Lifts, Dual Mast Lifts, Multi-Mast Lifts, as well as a comparison between Self-Propelled and Push-Around Lifts, and an analysis of the differences between Hydraulic, Electric, and Pneumatic power systems.

1. Single Mast Lifts

Features:

Single Mast Lifts are compact and simple in design, featuring just one vertical mast. These lifts are lightweight and easy to maneuver, making them suitable for narrow spaces. They are ideal for light-duty tasks and can be used in environments where space is limited.

Applications:

Indoor Maintenance: Single Mast Lifts are perfect for tasks like changing light bulbs, cleaning windows, or performing minor electrical maintenance in confined spaces like offices, retail stores, or warehouses.

Electrical Inspections and Repairs: Their narrow footprint makes them ideal for electrical work, allowing workers to access high areas in tight or crowded environments.

Single Mast Lifts are best used for quick tasks that require mobility and flexibility in smaller work areas.

2. Dual Mast Lifts

Features:

Dual Mast Lifts feature two masts that provide additional stability and lifting power. These lifts are larger than Single Mast Lifts and offer a higher maximum reach, making them more suitable for medium-duty tasks. The dual mast design ensures greater balance, allowing the platform to operate safely at higher elevations.

Applications:

Large Facility Maintenance: These lifts are commonly used in larger facilities such as factories, warehouses, and airports, where workers need to reach higher areas while maintaining stability.

Exhibition Setup: The increased height and stability make Dual Mast Lifts ideal for temporary setups such as trade shows or exhibitions, where workers need to install or adjust equipment at various heights.

Dual Mast Lifts are better suited for environments where stability and higher reach are needed for tasks requiring more time or precision.

3. Multi-Mast Lifts

Features:

Multi-Mast Lifts are designed for high-reach operations and heavy-duty tasks. These lifts typically feature multiple masts, which allow for a higher load-bearing capacity and an elevated working height, often up to 50 feet or more. The multi-mast configuration distributes the weight evenly, providing maximum stability for tasks performed at great heights.

Applications:

Airports: Multi-Mast Lifts are ideal for large facilities like airports, where high ceilings and expansive spaces require workers to perform maintenance or repairs at great heights.

Theaters and Auditoriums: These lifts are also used in theaters where maintenance work at significant heights is common, such as cleaning lights or adjusting equipment.

Large Industrial Facilities: Multi-Mast Lifts are suited for warehouses or factories with high ceilings, offering stability and reach for tasks like inventory management, maintenance, and installations.

These lifts are designed for environments with large vertical spaces where both high reach and heavy-duty support are necessary.

Self-Propelled vs. Push-Around Lifts

Comparison of Self-Propelled and Push-Around Lifts:

Self-Propelled Lifts: These lifts come with built-in motors, allowing the operator to move the lift while elevated. Self-Propelled Lifts are more efficient because the operator can control both the movement and the lifting function simultaneously, reducing the time spent repositioning the lift.

Push-Around Lifts: Push-Around Lifts require the operator to manually move the lift from one location to another. These lifts are typically lighter and more compact, making them easier to transport and store. However, they are less efficient for large tasks, as they need to be manually repositioned after every use.

Self-Propelled Lifts are ideal for larger tasks and areas where the lift needs to be moved frequently, while Push-Around Lifts are suitable for smaller jobs with less need for mobility.

Hydraulic vs. Electric vs. Pneumatic Power Systems

Power System Differences:

Hydraulic Systems: Hydraulic lifts use a system of fluid pumps and cylinders to create lifting force. They are known for their power and smooth operation, making them ideal for heavy-duty tasks. These lifts are more durable and can handle larger loads, but they typically require more maintenance and regular fluid checks.

Electric Systems: Electric lifts are powered by batteries and electric motors. They are quieter, more energy-efficient, and produce fewer emissions compared to hydraulic systems. Electric lifts are often preferred for indoor environments where noise and pollution need to be minimized. However, electric lifts generally have a lower lifting capacity compared to hydraulic ones.

Pneumatic Systems: Pneumatic lifts operate using compressed air to lift the platform. They are used in environments where electrical or hydraulic power may not be suitable, such as areas with hazardous materials. Pneumatic lifts are less common than hydraulic and electric lifts and are typically used for lighter tasks or in specialized environments.

Recommended Environments:

Hydraulic: Best for heavy-duty outdoor tasks or environments where high lifting power is needed.

Electric: Ideal for indoor work in quiet, low-emission environments, such as warehouses, retail stores, and hospitals.

Pneumatic: Most suitable for environments where sparks or electrical hazards are a concern, such as chemical plants or explosive atmospheres.

Each power system has distinct advantages depending on the specific needs of the environment and task.

Choosing the right type of Vertical Mast Lift depends on various factors such as height, weight capacity, maneuverability, and the environment in which it will be used. Whether it’s a Single Mast Lift for tight spaces, a Dual Mast Lift for stability, a Multi-Mast Lift for extreme reach, or a choice between Self-Propelled and Push-Around Lifts, the right lift can increase efficiency and safety for various work tasks. Additionally, selecting the appropriate power system (Hydraulic, Electric, or Pneumatic) ensures that the lift is best suited for the work environment and requirements.

Applications of Vertical Mast Lifts

Vertical Mast Lifts are versatile and efficient tools used across various industries for tasks that require elevated access. Below are some of the primary applications:

Mall, Warehouse, and Office Building Maintenance

Vertical Mast Lifts are ideal for maintaining large commercial spaces like shopping malls, warehouses, and office buildings. These lifts provide easy access to high ceilings for tasks such as cleaning windows, replacing light bulbs, or conducting HVAC inspections. Their compact design allows them to navigate narrow aisles, making them perfect for environments where space is limited.

Indoor Electrical and Lighting Installation

These lifts are commonly used in indoor electrical and lighting installations. Whether it’s installing or repairing lighting systems, running electrical wiring, or performing routine electrical inspections, Vertical Mast Lifts provide a stable platform for workers to safely reach high areas, such as ceilings or tall shelving units. Their ease of movement and ability to work in confined spaces make them a great choice for electrical work in commercial buildings, schools, and hospitals.

Stage Setups and Exhibition Arrangements

Vertical Mast Lifts are frequently employed in the entertainment and exhibition industries. For stage setups or event exhibitions, these lifts help technicians and workers to position lighting, speakers, or other equipment at elevated heights. Their compact size allows them to maneuver easily in crowded spaces, ensuring efficiency in environments like theaters, concert venues, or trade shows.

Factory Inspections and Equipment Maintenance

In factories, Vertical Mast Lifts are used for maintenance and inspection tasks, such as servicing machines, replacing parts, and inspecting overhead equipment. They provide easy access to high, hard-to-reach areas like overhead conveyors, electrical panels, and roof-mounted systems, making them essential tools for ensuring that industrial operations run smoothly.

Routine Work in Medical and School Buildings

Vertical Mast Lifts are also used for routine maintenance in medical facilities and schools. Whether for cleaning, electrical work, or general building upkeep, these lifts provide a safe and efficient way to access high areas. They are particularly useful in settings where frequent maintenance and repairs are required in environments with high ceilings or narrow hallways.

In summary, Vertical Mast Lifts are valuable for a wide range of applications that require elevated access in both indoor and confined spaces.

Benefits of Using Vertical Mast Lifts

Vertical Mast Lifts offer a variety of advantages that make them highly popular in many industries requiring elevated access. From maintenance tasks in commercial buildings to event setups, these lifts provide practical solutions with numerous benefits. Here are some of the key benefits of using Vertical Mast Lifts:

1. Compact Design, Ideal for Tight Spaces

One of the standout features of Vertical Mast Lifts is their compact design. Unlike other types of elevating platforms, Vertical Mast Lifts are narrow and can easily fit into tight spaces such as narrow aisles, doorways, and crowded environments. This makes them ideal for use in environments like warehouses, retail stores, and office buildings where space is often limited. Their small footprint allows for easy maneuverability, ensuring that workers can access high areas without needing to navigate larger, bulkier equipment.

2. Simple Operation and High Safety Standards

Vertical Mast Lifts are known for their user-friendly operation. They feature straightforward controls that allow operators to lift and lower the platform with minimal training, which enhances productivity and reduces the chance of user error. In addition, these lifts are equipped with various safety features such as stable platforms, non-slip surfaces, and limit switches to prevent overextension. These safety mechanisms make Vertical Mast Lifts a reliable option for work at height, significantly reducing the risks associated with falls and accidents. The simplicity of operation and the built-in safety features make them a safer choice for both experienced operators and novices.

3. Cost-Effective (Compared to Other Aerial Work Platforms)

Vertical Mast Lifts offer a cost-effective alternative to other types of aerial work platforms, such as scissor lifts or boom lifts. They are generally more affordable to purchase or rent, making them a great option for businesses or contractors on a budget. Additionally, their compact design and lower operating costs contribute to their overall affordability. The energy-efficient electric models also offer low maintenance costs, making them a practical choice for long-term use. The combination of affordability, functionality, and low maintenance requirements makes Vertical Mast Lifts a cost-effective solution for businesses across various industries.

4. Customizable to Meet Specific Needs (Height, Drive Type)

Vertical Mast Lifts come in various models that can be customized to suit specific tasks or environments. Depending on the height requirements, different models are available, ranging from compact models for low-height tasks to larger models for elevated work at greater heights. Additionally, these lifts can be equipped with either manual or self-propelled drive systems, offering flexibility based on the level of mobility needed. Operators can choose the appropriate lift configuration depending on the nature of their work, whether it’s for small indoor maintenance or large-scale facility work. The versatility in drive types and lift heights allows businesses to select the most suitable model for their operations.

5. Improved Work Efficiency and Personnel Safety

Using Vertical Mast Lifts can greatly increase work efficiency. Their ability to quickly and safely elevate workers to desired heights eliminates the need for ladders or scaffolding, reducing the amount of time spent setting up and ensuring that workers can focus on their tasks. Additionally, the platform's stability and safety features minimize the risk of accidents, allowing workers to perform tasks with peace of mind. The lifts help to improve the overall safety of the workplace by providing a stable, secure platform, reducing the risk of falls, and limiting the need for workers to use less reliable tools like ladders or scaffolds. The combination of increased efficiency and enhanced safety results in a more productive and secure working environment.

In summary, Vertical Mast Lifts offer several significant benefits, including a compact design for tight spaces, simple operation with high safety standards, cost-effectiveness compared to other aerial platforms, customization options for different tasks, and improved efficiency and safety for workers. These advantages make them an essential tool for a variety of industries, from building maintenance to event setups, ensuring that work at height is done safely, efficiently, and cost-effectively.

How to Choose the Right Vertical Mast Lift

Choosing the right mast lift for a specific task is crucial to ensure efficiency, safety, and cost-effectiveness. Several factors need to be considered before making a selection, including the work height, frequency of use, the operating environment, and whether you need a manual or self-propelled model. Below, we will discuss these factors in more detail to help you make the best decision.

1. Choose Based on Work Height

The first and most important factor when selecting a vertical mast lift is the height at which you need to work. Different models of mast lifts are designed for varying heights, so it’s essential to match the lift’s maximum reach with the specific requirements of your tasks. For example, if you need to access heights of up to 20 feet, a compact Single Mast Lift would suffice. However, for tasks that require working at greater heights (e.g., 30 feet or more), you may need a more robust Dual or Multi-Mast Lift. Always choose a lift that provides enough working height with a margin for safety, ensuring that the platform can comfortably accommodate the job at hand.

2. Consider Operating Frequency and Environment

Another important consideration is the frequency of use and the working environment. If the lift will be used frequently or for extended periods, it's important to select a durable and reliable model. For high-traffic areas, such as factories or large retail stores, an electric-powered, self-propelled lift may be necessary to maximize mobility and efficiency. Additionally, if your work environment is confined (e.g., narrow aisles in a warehouse), a smaller, more compact model will be ideal to ensure the lift can maneuver through tight spaces. On the other hand, if you're working in an environment with rough terrain or outdoor conditions, a more rugged model with higher ground clearance and weather-resistant features may be required.

3. Push-Around vs. Self-Propelled

Another key decision is whether to go for a Push-Around Lift or a Self-Propelled Lift. A Push-Around lift is typically lighter and more affordable but requires manual effort to move it from one location to another. It is ideal for small, light tasks where mobility is not critical. In contrast, Self-Propelled Lifts have a built-in motor, allowing operators to move the lift while elevated. This can greatly improve efficiency in large spaces and areas where frequent repositioning is required. Self-propelled lifts are often preferred for tasks that involve extended use or when operators need to save time by moving the lift with minimal effort.

4. Brand Recommendation - TUHE LIFT

When selecting a Vertical Mast Lift, choosing a reliable brand with a reputation for high quality and cost-effectiveness is essential. TUHE LIFT is a leading lift manufacturer based in China, renowned for providing vertical mast lifts with excellent performance at competitive prices. With years of experience in design, development, and manufacturing, TUHE LIFT has established itself as a trusted brand both in China and internationally. Their products are known for their high cost performance and reliable quality.

TUHE LIFT has earned a strong reputation in the domestic and overseas markets, exporting to countries like the United States, Australia, Germany, Algeria, Peru, and many others. They offer a variety of customizable mast lift models tailored to specific customer needs, ensuring high efficiency, safety, and productivity for various tasks. Additionally, TUHE LIFT provides OEM services, allowing you to create bespoke solutions for your business. Whether you need a compact lift for light-duty tasks or a heavy-duty lift for more demanding applications, TUHE LIFT can provide the right solution.

Selecting the right vertical mast lift depends on multiple factors, including the height required, the frequency of use, the environment, and whether you need a manual or self-propelled model. By considering these factors carefully, you can ensure that you choose the most suitable lift for your needs. Brands like TUHE LIFT offer high-quality, customizable solutions that provide excellent performance and cost efficiency, making them a great option for businesses looking for reliable and durable lifting equipment.

Conclusion

Vertical Mast Lifts have become an essential tool in various industries, offering a range of options to suit different tasks and environments. The Single Mast Lift is ideal for light-duty work in confined spaces, providing easy access to lower heights. Dual Mast Lifts offer enhanced stability and higher reach, making them suitable for larger facilities and tasks requiring additional safety and support. Multi-Mast Lifts are designed for high-reach operations in expansive spaces, such as airports and large industrial settings, providing excellent load capacity and stability.

The benefits of Vertical Mast Lifts, including their compact design, easy operation, and cost-effectiveness, make them a preferred choice for workers in a variety of industries. These lifts not only improve operational efficiency but also ensure greater safety by providing stable platforms for workers to perform tasks at height with confidence. Additionally, the ability to select different models based on height requirements and mobility needs further enhances their versatility and makes them a valuable investment for any business.

In today’s world, where high-altitude tasks are increasingly common in sectors such as maintenance, construction, and event setups, Vertical Mast Lifts play a pivotal role in ensuring safe and efficient operations. Their compact nature, ease of use, and cost-efficiency make them indispensable for both small-scale and large-scale projects.

For those interested in learning more about these lifts and finding the right solution for their needs, TUHE LIFT is a trusted and reliable provider of high-quality Vertical Mast Lifts. With years of experience and a reputation for delivering durable, cost-effective solutions, TUHE LIFT is committed to helping you find the best lift for your specific requirements. Contact TUHE LIFT today to explore their wide range of products and discover how their lifts can improve your operations.

660.webp)

503.webp)

695.webp)